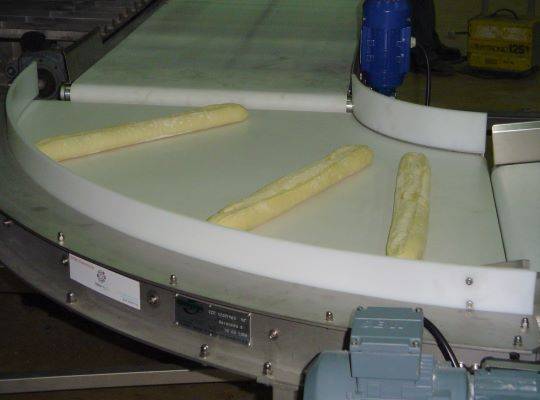

SRI Belt Bend Conveyors

The SRI belt bend conveyors, which are based on the CCD model, are designed

without an inside radius, and with parallel rollers with a 45 mm diameter.

This technology guarantees:

- Making a half-turn (180°) with extremely small overall dimensions

- A uniform and regular speed

- An optimal transfer of light loads and small pieces

- A particularly silent functioning

- A perfect tracking without slipping and sliding

As the CCD model, the SRI conveyors are valued for their small overall dimensions, their simple design, their lightness and their moderate cost. 45 mm end diameters enable conveying small items such as newspapers, books, printed advertising matter, envelopes, food products (chocolate, biscuits, coffee, etc.), stacks of laundry, plastic injection parts, fragile packaging (perfume, makeup, medicine, etc.), electronics and small metal items.

SRI Technical Data

- 45 mm diameter parallel rollers

- Conveyor belt guided by chain

- 180° angle

- Conveyor belt working widths from 500 to 1 100 mm

- Maximum load: 10 to 30 kg

- Maximum speed up to 25 m/min

- Feet adjustable +/-50 mm

- Sew Usocome 220/400 V three-phase engine, direct assembly of a hollow shaft

- Minimum allowable room temperature: 3°C

- Made of painted or stainless steel

SRI Options

- All RAL paint colours in epoxy paint

- Customization with specific rails (version N) for high speeds

- Automatic chain lubrication device

- Conveyor belts available in felt and polyester

- Side edges in steel – stainless steel – plastic, etc.

- Wheel casters with brake

- Double direction of rotation

- Speed regulator